How the ‘Sake Lees Extract,’ is made.

‘Sake lees extract’ is one of the main ingredients in KURAMOTO-NO-SHIZUKU. As many of you may know, this sake lees extract is made from sake lees, a by-product created during the process of making sake. This time, let’s take a look at the processes and techniques used to make sake lees and sake.

The person with ultimate responsibility for making sake = Toji (master brewer).

Those who are familiar with KURAMOTO-NO-SHIZUKU have likely often come across the term ‘Toji.’ A Toji is the person with the highest responsibility in sake brewing. They oversee the delicate brewing process with advanced brewing skills and knowledge. Most Toji hold a national qualification called ‘Sake Brewing Technician,’ possessing specialized knowledge and skills in the field of sake making. Additionally, they also have the role of supervising and leading the kurabito (brewery workers) who work under them.

The process of sake brewing

Sake brewing is such a delicate process. It requires an extraordinary amount of time, effort, and skill that is unparalleled globally. Let’s take a look at the processes involved in making sake and sake lees.

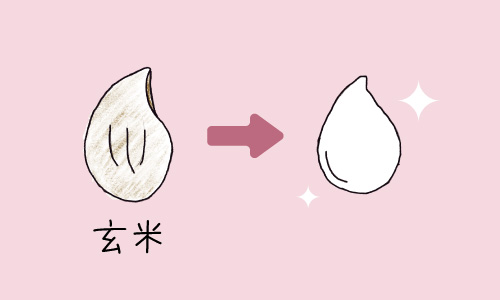

・Rice Polishing

The process of making sake begins with polishing the rice, which is the base ingredient for sake. Brown rice contains unnecessary components, such as lipids and proteins, in addition to the starch required for sake production. If the rice is used as is, these components can lead to off-flavors, so the rice is polished to remove the excess parts. The more the rice is polished, the more raw material is used, and the higher the level of skill required.

・Steaming

After polishing, the rice is steamed to incorporate the appropriate amount of moisture for sake brewing. Steaming alters the starch in the rice, creating a sticky, glue-like texture. This prepares an environment for the enzymes in the sake koji to function effectively.

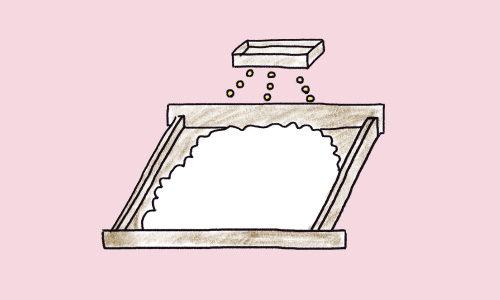

・Koji Making

After steaming, the rice is cooled to just the right temperature before adding and sprinkling in the koji (the starter for koji) to promote its growth. This is the most important step in sake brewing, as the quality of the koji significantly influences the flavor of the sake.

By cultivating the koji mold, the starch in the rice is converted into sugar, which yeast then transforms into alcohol, resulting in sake. Additionally, the koji mold plays a key role in producing the umami flavor of the sake.

The most critical factors in the koji production process are managing the appropriate temperature, insulation, and ventilation. The optimal temperature for koji mold growth is between 30 to 40 degrees Celsius; it does not function below 15 degrees and dies if it exceeds 50 degrees. Moreover, the koji mold generates heat and carbon dioxide during its growth, so proper air circulation is necessary to ensure successful cultivation. By carefully managing these details, the koji is successfully produced.

・Moromi

Once the koji is complete, the steamed rice, koji, water, and yeast are combined. At this stage, the koji converts the starch into sugar, and the yeast transforms the sugar into alcohol.

・Fermentation

The mash is fermented. When fermenting the mash, if all the ingredients are added at once, the yeast may become diluted, leading to a decrease in acidity and an increased risk of contamination by unwanted bacteria and wild yeast. Therefore, the mash is added in three stages, allowing it to ferment slowly.

Additionally, during fermentation, the temperature fluctuates due to the heat generated by the fermentation process. For about a month, the Toji monitor the condition of the sake and the temperature daily, using a T-shaped wooden stick called a ‘kai’ to stir and adjust the mixture.

・Squeezing

Once fermentation is complete, the moromi is pressed to separate the sake from the sake lees. The timing of the pressing determines the flavor of the sake, so various factors, such as the sake brewery, type of sake, climate, and component analysis values, are carefully considered in this decision. The solid material left after pressing becomes sake lees.

・Lees removal

The pressed sake is slightly cloudy, mixed with small solid particles called ‘ori’ that could not be completely pressed out as sake lees. In the lees removal process, the sake is left to sit in the tank, allowing the sediment to settle. This way, only the clear portion can be extracted, resulting in a clean and refreshing sake. There are also products that intentionally leave the lees in the sake or blend the settled lees with the sake.

・Filtration

Filtration is performed to remove even finer lees. By using a filtration machine with activated charcoal or filter paper, the liquid, which was previously yellow, becomes a clear, transparent sake.

・Pasteurization

Finally, pasteurization is performed to heat-treat and sterilize the sake. By heating it at a low temperature of 60 to 65 degrees Celsius, the activity of the enzymes is halted, and the quality of the sake can be maintained consistently.

・Completion!

With this, the sake and sake lees are complete! From the sake lees produced here, ‘sake lees extract’ is extracted, and the production of KURAMOTO-NO-SHIZUKU begins.

Summary

This time, we focused on the sake brewing process. Sake is made through a series of delicate and lengthy steps, each of which is crucial and indispensable. Therefore, producing sake is considered to require a higher level of knowledge compared to making other alcoholic beverages. Kuramoto no Shizuku lavishly utilizes the sake lees extract, which is a crystallization of the Toji’s wisdom. When you take Kuramoto no Shizuku in your hands, please consider the Toji’s thoughts and intentions as you use it.

コメント